Internet Shopping

Boy, have I had fun shopping in cyberspace lately. Remember the old days when the ‘modern’ thing to do was ‘let your fingers do the walking?’ This is lightyears beyond that!

Internet shopping is hardly new, but the wealth of websites devoted to weaving/spinning/lace making/sewing….etc…etc has expanded into a galaxy of wonderful places to shop!

A couple of posts back, pre-christening dress dilemma, I wrote that I had ordered a tape loom on etsy. Well, it arrived! And it was beautifully packaged so that opening the box was like a well choreographed dance. I enjoyed every moment of unpacking this treasure! I hope I can get a warp on it, and figure out how to get it to Pandora, now that she sailed away with Bob–OR rather, Bob sailed away with her.

The woman who made this loom and all the accessories that go with it calls herself HandyWOman. What an attention to detail! My loom has images of England and Scotland branded (?)/burnished (?) into it on all sides, inside and out! The accompanying bag (sold separately) is so well made– it shows the kind of sewing expertise that I am trying to attain in my classes! Just take a look!

Here is the box with the first bit unpacked. She made the drawstring bag that holds some small items you’ll see shortly!

I enjoyed the unpacking process and had to document it! The rigid heddle is embellished with a Tudor rose.

The set came with this little Scottie dog comb–adorable!

Everything unpacked and displayed on the kitchen table! I wish I’d gotten a better shot of the London skyline on the side of the loom that is being blocked by the instruction papers.

You need to see a closeup of the tote bag that holds all the pieces with plenty of extra room for other stuff. Note that HandyWOman’s logo has been machine embroidered on the top of the bag. What a great touch! I’m finding it hard to believe that she can be such a good wood worker as well as such an accomplished seamstress.

I can’t wait to try weaving on it!

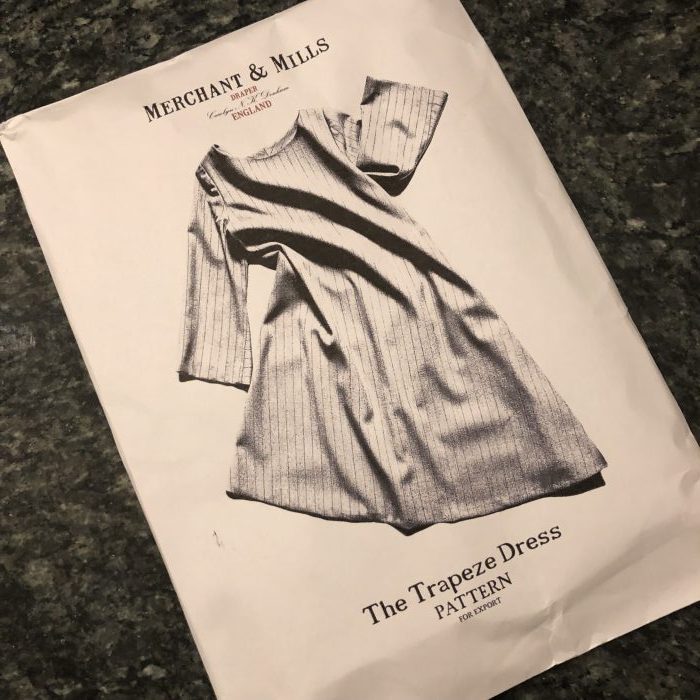

Going back a couple of weeks now: my lace group made a trip to the Windham Textile and History Museum in Willimantic. My friend Mary descends from some mill workers and foremen, so she has particular interest in this time period. She was searching the internet for some mill related information and found the clothing designer Carolyn Denham (of Merchant and Mills) who makes timeless yet modern clothing with a nod to the mill workers of years ago. I couldn’t resist ordering this pattern, and today I found it in the mailbox! There’s no time to make it now, but hopefully I can tackle it in the spring when I return. In fact, I hope Mary makes it while I’m away so she can give me pointers on the process!

Last week I went to an extra sewing class on a day I don’t usually go. There were students there I hadn’t met before, and lots of projects to sigh over. One woman is making her granddaughter a quilt out of large and small panels of woodland animals drawn in a wonderfully graphic style. I love the owl and the fox and think that Tori would love them too! So, of course, I had to go hunting for them, letting my fingers do the walking so to speak, across the keyboard rather than the phone dial of old….and they were easy to find! They also arrived in my mailbox today! (The panels are from fashionable fabrics)

There are actually four animals in this set. I’m smitten with the owl and the fox so that’s what I’ve photographed. There are also a bear and a bunny. I bought the coordinating fabrics at the top of the photo at a local fabric store in Glastonbury called Close to Home. I’d never been there before, but I will be going back in the future. I just love the addition of that kiwi green and hope Tori will too.

The arrival of these treats could not have come at a more opportune time! It’s post-christening dress trauma and just in time to plan things to work on when I return home in the spring!