It’s January, the first month of the new year as well as my birth month. It’s the month when the ancient god Janus for whom the month gets its name, compels us to take stock of where we’ve been and what we’ve done as we look to the future for where we’re going and what we’ll do. He is the god with two faces, looking forward and looking back. He predates the Roman gods and is likely a god from Etruscan origins. The Etruscans are near and dear to me, in spite of what little is known of their culture. Their artwork is glorious and is seen in subsequent centuries in Roman culture. I visited Tarquinia in the late 1970s, in college, where there are many Etruscan tombs with artwork still intact. I had the thrill of being there again a couple of months ago, in October. The images of Etruscan artwork are prominent in my mind this month as I plan for the future.

This is my last year in my 60s. This is a year where I want to pay particular attention to looking back so I can determine where and how I want to go forward Into what will hopefully more than a decade of continued creativity. I know I have to keep de-stashing and even more importantly, I want to create things. I realize I must clear some space both physically and mentally in order to create. I am becoming bogged down in my own stuff. Someone else, younger, with more years of creativity in their future, needs to take some of this burden off my hands.

I’ve been in Antigua for 6 days now. I was treated to a quick tropical squall on the morning of my birthday, followed by a beautiful rainbow.

Then the day progressed with getting a cooking/baking lesson with the French chef of La Brasserie in English Harbour, Antigua. Eric gave me a lesson in making macaroons with fillings. He made me a large macaroon cake which is called an ‘Ispahan’ in French. My macaron cake was scented with rose water, and the filling was a butter cream/custard mixture which I also learned to make, raspberry jam, and fresh raspberries. It’s wonderful to have a beautiful dessert that tastes as good as it looks.

It’s been a rather busy few days since we arrived in Antigua. We’ve met up with cruising friends who have either returned here or stayed here through the holidays. Some non-sailing friends visited during their winter vacation here. It’s their first time in Antigua, and setting aside the Christmas winds that have arrived bringing high winds and rain, I think they are enjoying the island.

Today is our first day with no scheduled events, so we took our dinghy to a new breakfast place called You and Me. It has well shaded outdoor seating area with great views of the head of Falmouth Harbour.

After I finish this blog post I intend to knit for most of the day. My older son gave me a wonderful selection of yarn for Christmas. It’s from a local shop near him, and the yarn is “Yarn Citizens Luxe.” He bought five colors: Pearl (close to white), Heather (barely lavender), Jasmine (medium lavender), Ocean (medium indigo), and Coal (medium charcoal grey). The yarn is 49% baby alpaca, 39 % mulberry silk, and 12% cashmere. I can barely feel it as I knit, and it looks like a cloud.

My goal this year is to concentrate on finishing many UFOs, but this gemlike yarn obviously took precedence. I’m knitting a simple top/down raglan sweater and will use the colors from palest at the neckline to darkest at the hem. Even with our busy schedule, I’ve made sure to have relaxing knitting time part of every day.

Looking back, I am more satisfied than I expected with my projects this year. I should make a record of them, and to help me accomplish that my younger son introduced me to the app called Notion a couple of years ago. Notion allows you to keep track of projects in motion, to keep track of the order in which one needs to tackle projects, and to keep a record of things accomplished. I still haven’t managed how to include photos with this work tracking app, so I haven’t used it to its best potential. On the other end of the organized spectrum, I have an older friend who records all her finished projects in a regular notebook with a printout of the photo she takes when she finishes something. I have not resorted to that method because I have a basic dislike of having a lot of notebooks taking up precious space on my shelves. The notebooks I already have are burdensome enough, not to mention the many decades of periodicals I have kept and the books I own. While these are all precious possessions to me, the lack of space is getting worrisome. Sometimes I feel I might get buried in my workshop and never escape. Learning how to better use Notion this year is pretty high on my list.

In November I was invited to participate in a textile arts exhibit at a private club in Hartford. I think there were only eight invitees, and two of us were new to this event. The exhibit will be on display for the months of January and February. The club held a lovely opening reception a couple of days before Bob and I left to come back to Antigua. I invited a good friend to join me, and when I arrived I realized I knew quite a few of the attendees, but only one of the other artists. It’s always inspiring to see what other textile artists do, and I came away with wonderful images in my head. I was the only tapestry artist on display.

I thought above the fireplace was a prime place for artwork, and I was honored to have a piece there. On the left are two felted landscapes done by the only other artist I knew from the group, Diane Cadrain. On the right is my tapestry “Sunset on Wilson Cove.”

To list the things I feel are accomplishments I’ve made this year, I might put this exhibit at the top of the list. It’s not often that textile artists have a venue to show their work, and I’m very glad I was asked and glad that I managed to pull some works together before leaving the country. I participated in two other shows during this year, and while that’s not much, it makes three events that brought tapestry weaving to the public.

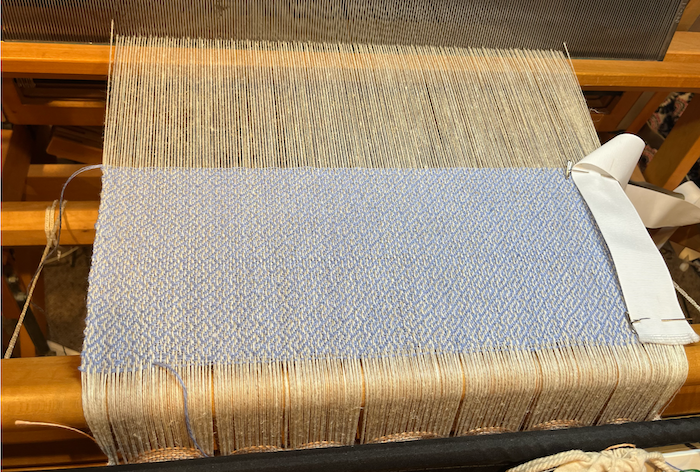

I did a lot of weaving this year. I finished half the warp of woven sashiko, and I made a number of sakiori samples which led to a vest that actually fits me and a tote bag I’m enjoying using. I have the tote bag with me now on Pandora.

Jody captured the best view of the vest which is from the back (althought it’s quite wrinkled from a long car ride!). There are side gussets of sakiori and two sakiori pockets on the front, but the back is almost entirely sakiori. Here’s the front—a photo also taken by my friend Jody.

The fabric for the trim on this vest is what I used as the fabric strips for weaving.

I wove my first wedge weave tapestry, wove half the warp of my sashiko project and gave away four of the finished squares.

At long last I finished the Caribbean tapestry that I began during the pandemic. I can’t post a photo of it because I plan to submit it the Connecticut biennial when I return home. What I can show is the wonderful frame Bob built for the tapestry. This is our best attempt so far at having the back be as neat and tidy as the front.

This fall I made some fabric trays for a party favor for an upcoming event I will not be able to attend, and I made three lace flowers that I included in a fascinator that was made from various pieces of antigue machine lace I have and several ribbon embroidered flowers that I’ve made over the years. That was a fun project initiated by my lace group to become a new category of lace at the Big E Arts and Crafts exhibition. The fascinators are now on display at a local library.

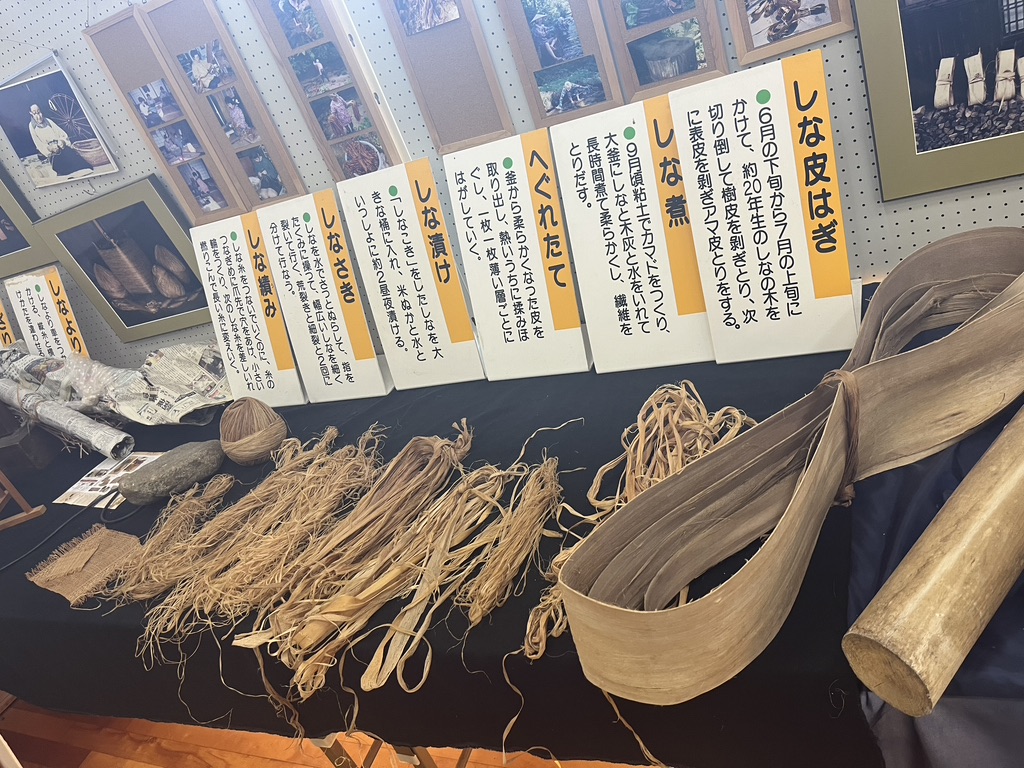

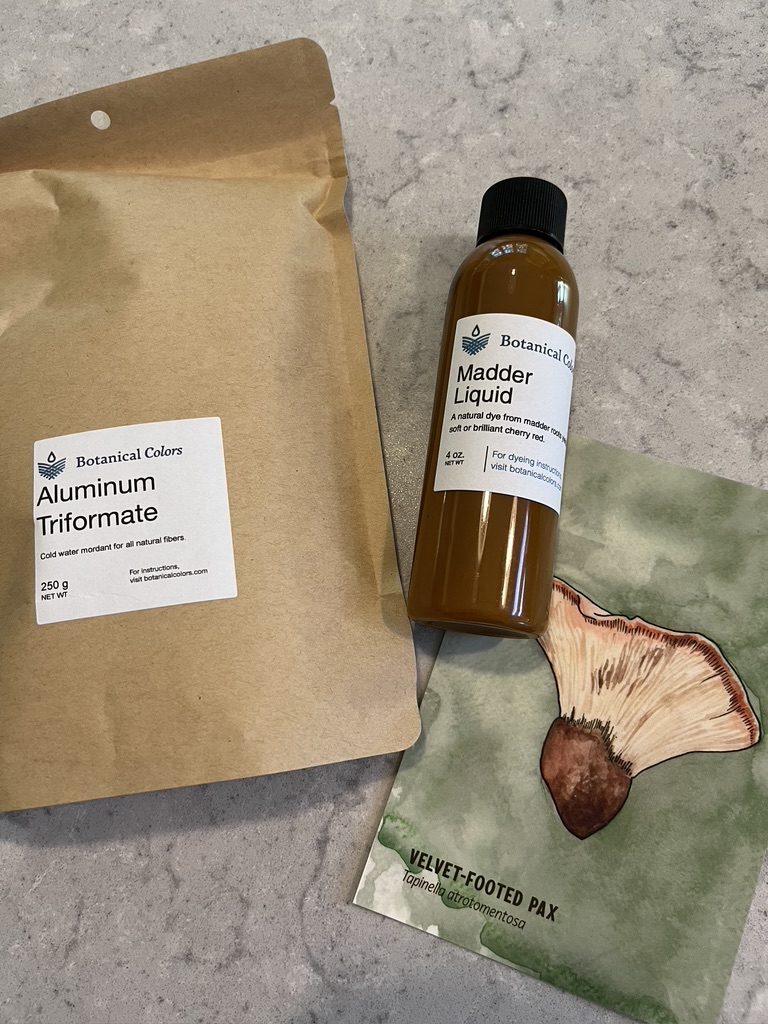

And then there was a little weaving and a LOT of dyeing in Umbria, Italy, which I wrote about here and here. In December my friend Jody and I put some of our new knowledge to work during a two-day dyeing session in my kitchen—right after the new year. We used indigo, weld, madder, and olive leaves and branches from my olive tree. It was hard to stop, and it’s one of the first things I want to do when I return home. The circle of colors starting on the lower right is 3 shades of maddder, , weld, olive leaves, weld with a short dip in indigo, two skeins in indigo (the first one is very blotchy, not sure why), and the last two are indigo dipped in madder. The last skein is close to a color I wanted to recreate from one of the skeins we dyed in Italy. I look forward to attempting that again at home this spring.

I also finished two knitted items this year: a vest with the yarns I got from the 2023 Kate Davies advent yarn box. It is tunic length and has a shadow knitting pattern running through it. The 2nd project is a sweater from a Kate Davies pattern called “Auchnaha.” I used her beautiful ooskit yarn in a natural grey/brown. I’ve enjoyed wearing both these sweaters before leaving New England for the tropical weather in Antigua.

Just before I left home I stopped at Hartford Artisans for a short meeting. It’s impossible to go there without being tempted by any number of wonderful handwoven/handmade things. This time I succumbed to this charming little pouch. It had a rather sad plastic button that imitated bronze. That just would not do! I changed the button to a shell, and added a shell to the plain commercial fabric at the top. I also added a piece of kumihimo from my stash of samples to turn the pouch into a wristlet purse. I’ve got it with me now in the Caribbean, and it is perfect here!

I’m pretty sure I have accomplished significantly more this year than in previous years. While it feels awkward and quite self-absorbed to list all my finished projects, I am trying to understand how I did these things, and how I can maintain this surge of work in 2025. It takes luck, of course, since we need good health to be productive, and that’s something none of us can predict. It’s time to knuckle down to learn more about Notion so I can keep better records, to de-stash my extensive work space, and get down to the business of doing what I love. Forward ho!